Floating Dock Brackets

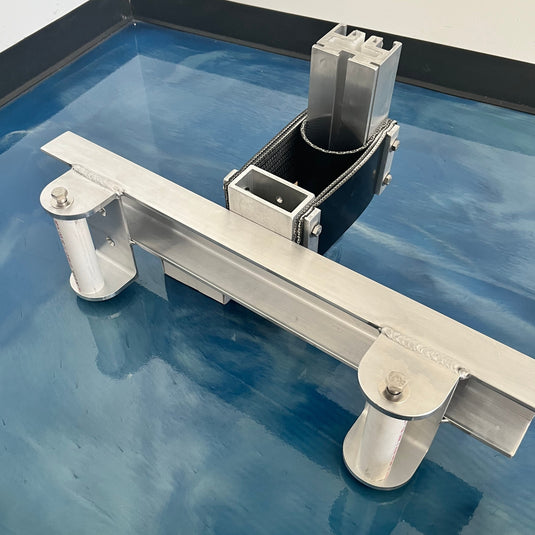

FLEX SLIDE

Introducing the Flex Slide, your go-to solution for attaching floating docks and jet ski ports with superior flexibility and performance.

FLEX SLIDE - PRO SERIES

For rough water environments, the Pro Series offers unparalleled performance, durability, and ease of use.

Flex Slide Accessories

Upgrade your Flex Slide system with our premium accessories designed for seamless docking and ultimate convenience. Whether you need extra stability, enhanced functionality, we’ve got you covered.

Explore our selection and customize your setup to fit your needs effortlessly!

FLEX SLIDE

Flexible Dock Brackets – a better way to attach floating docks or jet ski ports to bulk heads, sea walls or pilings!

Other dock brackets work like a door hinge, moving up and down on just two planes. But, wave action creates twisting and torquing which eventually tears things apart. Flex Slide™ incorporates two heavy-duty, flexible belts into the bracket which allow for full range of movement which dramatically reduces the stress on dock, bracket and piling. This also virtually eliminates the annoying squeaking and obnoxious noises that routinely come with the use of ordinary two-plane hinging dock brackets.

EXCLUSIVE POWER BELT TECHNOLOGY™

FLEX SLIDE– a better floating dock bracket!

Exclusive Power Belt Technology

The key to Flex Slide's full range of motion are these two flexible, heavy-duty Power Belts that twist and turn with the torquing caused by wave action. Other hinging dock brackets move only up and down like a door hinge.

Ideal for attaching floating docks or jet ski ports to bulk heads, sea walls or pilings.

THE BENEFITS OF OUR FLOATING DOCK BRACKETS

Full Range of Movement

The flexible belts allow movement in all directions, preventing stress from wave action.

Reduces Stress on Dock & Bracket

Prevents damage caused by twisting and torquing forces, increasing dock and bracket lifespan.

Quiet, Noise-Free Operation

Eliminates the squeaking and noises associated with traditional dock brackets.

Heavy-Duty Durability

Built with power belts that withstand harsh marine conditions, offering long-lasting performance.

Versatile Mounting Options

Suitable for attaching floating docks or jet ski ports to bulkheads, seawalls, or pilings.

Checkout Our Shock Block Video!

CHECK OUT OUR FLOATING DOCK BRACKETS

VIEW PRODUCT

TESTIMONIALS

CHECK OUT OUR FLOATING DOCK BRACKETS

VIEW PRODUCTS

FREQUENTLY ASKED QUESTION: FLEX SLIDES

Explore In-Depth Explanations and Insights to Help You Navigate Our Offerings. Everything You Need to Know.

Why should I pick the roller style vs. nylon slide?

The roller wheel style is ideal for rougher waters, allowing the flex slide to move quickly with minimal friction. It's especially recommended for areas with over 4 feet of tidal change, as the roller wheels experience less wear and tear compared to nylon inserts. They are highly effective in locations with frequent waves and boat wakes.

Can I attach to a floating dock on one side?

Yes, you can. Jet ski ports and boat ports are typically secured with just two flex slides on the same side. Customers have reported that this setup enhances the stability of the floating dock, even when attached on one side.

Will the flex slides be strong enough to hold a jet ski port or drive on a boat port?

Yes, they are strong enough for that purpose—that’s exactly what we designed them for.

How often do I have to do maintenance on them?

It can vary depending on the location. In areas with rougher water and higher tidal movement, we typically recommend replacing the slide material and rollers every two years. We encourage customers to monitor the wearable parts and replace them as needed to ensure everything continues to function smoothly.

What are they made out of?

We use extruded 6061 aluminum for the framework of the flex slides, and the hardware is made from 316L stainless steel. For the roller wheel style, we include sleeved nylon washers wherever the stainless bolts come into contact with the aluminum to prevent corrosion between the different alloys.